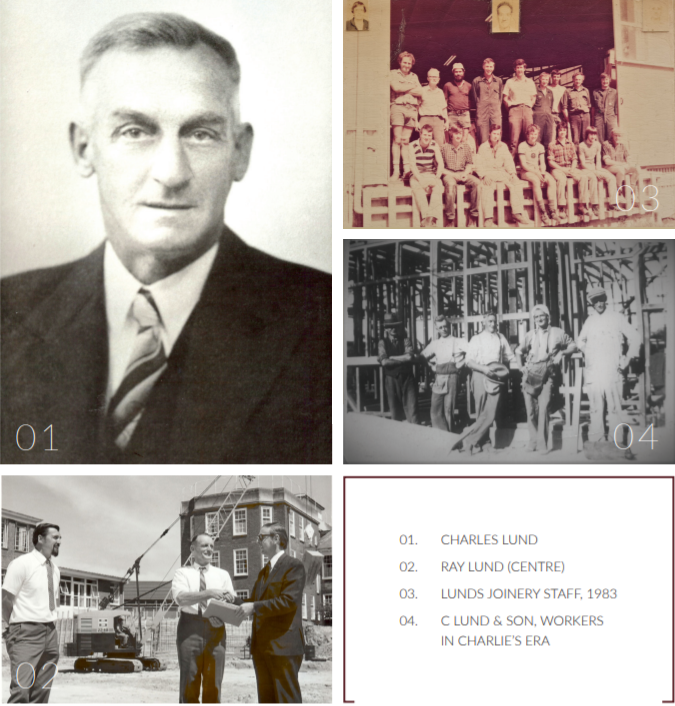

Our History

Lunds Joinery has been kicking up sawdust at Grants Road in Timaru for several decades; initially as a part of C Lund & Son Ltd and now as a standalone company.

C Lund & Son Ltd was established by Ray Lund as a limited liability company in 1956, but the Lunds were involved in the building industry well before that.

It all started with Walter Lund, who immigrated to New Zealand from Denmark in 1875. The grandson of a carpenter and shipwright, Walter landed in Napier and travelled south to Canterbury where he went into business as a carpenter and bridge builder.

Walter’s son, Charles Lund, followed in his father’s footsteps, entering the building trade as an apprentice in Pleasant Point. He went on to become a respected builder in Timaru with a reputation for being able to do complex calculations in his head. His advertising slogan was ‘C. Lund — the

Conscientious Builder’. Charles and his wife Barbara had six children and their only son, Ray Lund, eventually took over.

Ray incorporated the family business as a limited liability company in 1956, deciding on the name C Lund & Son Ltd to build on his father’s reputation. His sisters were involved too, particularly Thora Lund who kept the company’s books for 60 years. Thora was still working there in the 1960s when Ray’s son, Bruce Lund, took the helm alongside Charlie Kenny, a business partner of Ray’s who had joined the company after the war and become a shareholder.

Bruce had already been working for the company since his 18th birthday in 1956, when just a dozen staff worked out of the company’s original joinery shop in Church Street. He remembers a big motor in the roof space, from which the men connected belts made from buffalo hide to various joinery machines. Later on, by the time they’d moved to Grants Road, every item of plant had its own electric motor.

Charlie’s outstanding abilities as a self-taught quantity and land surveyor, despite having left school at just 13, eventually helped C Lund & Son Ltd pursue larger and larger contracts, including many with the Ministry of Works. Their first structural job was for a showroom and workshop for Andrews and Bevan, a machinery sales company, in 1949. The showroom block was two stories with concrete gables. “A terrific amount of hard work went on there,” said Charlie Kenney in an interview before he died in 2016. To be continued…